- Introduction

Alignment films (generally polyimide films) applied on glass substrates and rubbed onto the substrates are used to align liquid crystals uniformly. However, it is very difficult to quantitatively evaluate the effect of this rubbing. However, it is very difficult to quantitatively evaluate the effect of this rubbing, and a method to evaluate rubbing films by measuring the amount of birefringence has been discussed. In this article, we will introduce the results of a study on the effect of rubbing using birefringence. - Preparation of the samples

In this experiment, we prepared samples of two different alignment film materials and thicknesses. There are two types of rubbing methods: right-angle rubbing and diagonal rubbing. In this experiment, we prepared samples by using the right-angle rubbing method with the table speed and indentation amount as parameters.

- Sample :

Glass substrate: Material size, thickness; 20 x 25 mm, 1.1 mm

Alignment film: Spinner coating thickness; 1000, 200 Å

Alignment film material:

A1 : Alicyclic polyamide (similar to soluble polyimide) Firing 200°C, 60 min.

A2 : Aromatic polyamide (polyamic acid) Fired at 250°C, 60 min. - Rubbing conditions :

Table speed : 10,20,60,120 mm / sec.

Push-in amount : 0.3.0.5,0.7 mm

Number of passed : 1回

Substrate angle : 0゜

Number of rolls, diameter, rotation speed, rotation direction, angle : 1 roll, 148 mmφ, 500 rpm, positive rotation, 0°.

- Sample :

Evaluation method

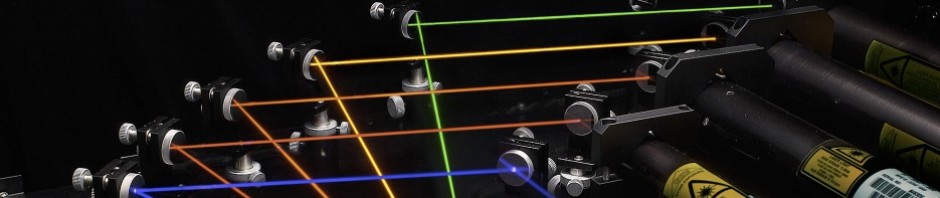

A measurement area is set up around the point to be evaluated (3 x 3 mm in this case), and the measurement laser beam is scanned in a stepwise manner over the area (16 points in this case) to measure the retardation Re and retardation axis azimuth angle Φ. The laser beam is scanned stepwise over the area (16 points in this case) to measure retardation Re and retardation axis azimuth angle Φ. From the retardation Re and retardation axis orientation angle Φ obtained from the measurement

From the retardation Re and retardation axis orientation angle Φ obtained from the measurement

(1) Average value of retardation Re(x)

(2) Standard deviation (3σ) of the retardation axis orientation angle Φ

to quantitatively evaluate the effect of rubbing.

Language

-

Recent Posts

Archives

- April 2025

- December 2024

- July 2024

- March 2024

- November 2023

- August 2023

- March 2023

- December 2022

- July 2022

- May 2022

- December 2021

- August 2021

- April 2021

- December 2020

- August 2020

- February 2020

- December 2019

- October 2019

- September 2019

- August 2019

- January 2019

- December 2018

- August 2018

- July 2018

- March 2018

- December 2017

- August 2017

- July 2017

- March 2017

- February 2016

- December 2015

- July 2015

- June 2015

- January 2015

- November 2014

- October 2014

- August 2014

- June 2014